|

|

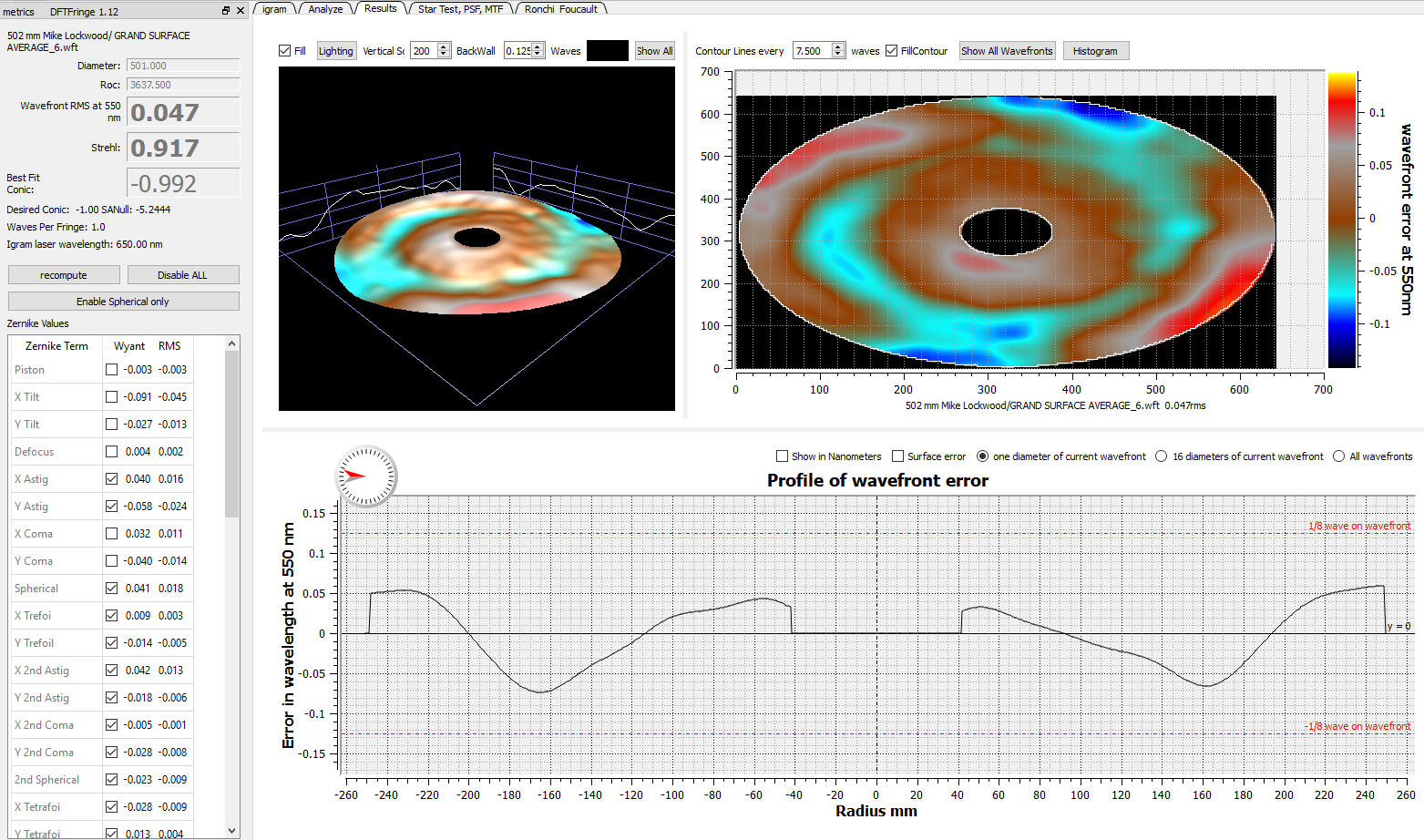

After reading some good stories about very fast telescopes, I decided to get rid of the ladder I needed for my 20 inch f/5 Dobsonian and ordered an f/3.6 mirror from Mike Lockwood (Lockwood Custom Optics). The mirror plus the 4.5" secondary, tested by Mike before coating, arrived on May 21st (2009). Important to note is that the mirrors were very, very well packed. I am absolutely sure they would have easily and without any scratches, survived an airplane crash followed by an elephant stampede (which is, thinking about the arrival condition of less carefully packed things I have received over the years, not much worse then being shipped from the US to the Netherlands). The primary is about 1.5 inch thick and weights 15.2 kilo's (33.4 Lbs), which is about two-thirds the weight of my 20" f/5 mirror.

I had already decided not to build a completely new telescope for this mirror, but rebuild my trilateral computerized 20" f/5 telescope (link in the menu below). The only things I had to change were the secondary cage and the truss assembly. I needed some extra weight for balancing, reason why I choose to build an eight-truss system instead of a six-truss system. So rebuilding really wasn't much work at all. Eyepiece heigth is 170 centimeters, so even I (173 centimeters) can look in the eyepiece standing with both feet on the ground. Assembling and disassembling the scope takes less then 15 minutes, connecting the laptop, batteries and electronics for the Mel Bartels drive system included. |

The mirror cell |

The secondary cage and wire spider

|

|

The secondary cage consists of two 15 mm thick baltic birch plywood rings, with 20 mm diameter tubes between them. I didn't use only one ring this time, because of the weight of the secondary (745 grams) and the weight of the focuser plus paracorr and eyepiece. And I find a cage much easier to transport to a dark site, because I don't need an extra box for the ring assembly: the cage is already a box.

The spider is a wire spider, made of 0.48 mm diameter metal cable. The distance between higher and lower attachement points is 150 millimeters. The hub is made of 15 mm square and 12 mm round tubing and is very lightweight. The secondary mount is a piece of 110 mm diameter, 2 mm thick aluminium tubing. The secondary is glued to the mount with three RTV blobs. To make the mount as lightweight as possible I have drilled (not visible on the photograph) lots of 12.5 mm wide holes in it. The wire spider supports the 1.1 kilo (2.4 lbs) secondary/holder assembly very well. The collimation is stable from zenit to horizon. |

Connecting the trusses to the morror box and secondary ring

|

| To connect the trusses to the secondary cage and the morror box I used the same method I used for the five 12 incher I build some time ago (link in the menu below), as can be seen on the picture above. The trusses stay connected. They are made of 20 mm diameter 1.5 mm wall thickness aluminium. |

Go-to and tracking: The 'Celano' controllerTo drive the scope with the Celano controller, a Dutch made stepper system, I use timing belts and pulley's. Below are some photographs of the drive system. The rollerskate type bearings are in the round white deltin 'blocks'. |

azimuth and altitude drive

close-up azimuth drive

|

close-up altitude drive

|

azimuth and altitude drive, controller and handpad on the telescope

|

Performance

|